I got all the interior details finished. I made two matching wheels house covers that will attach to the casket floor. Got some thick styrene strips cut...

And then made this wood guide to have something to bend them to correct to shape:

This stuff is so thick, it takes a lighter to bend it. Then I scored the ends to snap them off at the correct length:

Here's the finished pieces all assembled with decorative "vinyl" padding and upward directed lights:

The lights point up at these (got a mold and cast made of this so I could have two identical carvings):

Also got the upper portion of the partition created. The slot in the middle is for the "glass" to sit in:

Pretty much all that's left to do is mold and cast all the pieces and then primer and paint!

Creating scale resin models of Professional Cars, including hearses, flower cars and ambulances.

Saturday, December 19, 2015

Wednesday, December 16, 2015

Casket Table

Progress continues with these interior details. I finished the rear 3 interior door panels and put the finishing touches on the casket table and partition. Here you can see the rear loading door panel:

And the casket floor joined with the lower portion of the partition. These were done with thick sheets of styrene plastic which was heated with a lighter and then bent into shape. The partition is made of two thick pieces with a thin center sheet below them, creating a groove for the partition "glass" to sit in.

And finally, these are the panels inside the landau panel area of the car, which the diamond shaped panels with the "wood" appliques attach to.

And the casket floor joined with the lower portion of the partition. These were done with thick sheets of styrene plastic which was heated with a lighter and then bent into shape. The partition is made of two thick pieces with a thin center sheet below them, creating a groove for the partition "glass" to sit in.

And finally, these are the panels inside the landau panel area of the car, which the diamond shaped panels with the "wood" appliques attach to.

Sunday, December 6, 2015

Mold Making!

After completing my sculpt of the Masterpiece, with clay underneath to prevent the silicone mold material from going under the car, I was ready to pour the silicone and let it sit over night.

I got the exterior mold all created...

After making a basic cast, I chopped the top and attached it to the original lower body. With this I'll be able to add the interior details and create an interior mold.

Almost there! Be sure to order now (Buy it Now button off to the right) if you want it there by Christmas. =D

I got the exterior mold all created...

After making a basic cast, I chopped the top and attached it to the original lower body. With this I'll be able to add the interior details and create an interior mold.

Almost there! Be sure to order now (Buy it Now button off to the right) if you want it there by Christmas. =D

Sunday, November 22, 2015

Waterslide Decals

I got some clear decals made up for the interior wood appliques and the "S&S Masterpiece" badges on the exterior landau shield area. VERY tiny and hardly visible to the naked eye, but add a nice little detail.

Sunday, November 15, 2015

Windshield and Window Work

I got some work done on the shape of the commercial glass side windows and their trim. Of course after creating the mold and resin cast, the windows can be cut out and fitted with clear windows.

Adding styrene plastic to the sides will give a structural shape visible through the "vinyl" top, the way the 1:1 version appears. I added a center crease to the rear door, but still have a lot of work to do on this with adding trim, door handle and vinyl treatment.

I was happy to get the commercial glass windshield formed (Thanks for the measurements, Brady!)

Next thing to do is finish the trim, rear door, coach lamps and "S&S Masterpiece" badges and then I can do the vinyl top! I got a lot of requests for Cobra grain, so that's what it'll be.

Sunday, November 8, 2015

Progress

I've now got the basic shapes of the top formed. I just need to cover the wood with clay (To imitate the Cobra top) and styrene for the windows.

I got a little work done with putting the trim on the upper door frames and making rollers for the casket floor.

I got a little work done with putting the trim on the upper door frames and making rollers for the casket floor.

Sunday, October 25, 2015

Creating a new top...

So, I've been working on making a new top for the car out of balsa wood. Just getting the profile right for now, but I'm going to visit a Masterpiece this week and get some more measurements for the windshield and roof. This balsa will only be used to create the OUTER part of the mold. After that a hollow cast can be made and once details are added to the inner part, I can make the inner mold.

Saturday, October 17, 2015

Decorative Interior Panel

More to come! I will try to post a new update every Saturday, so stay tuned...

Top Chop

In preparation for making a new raised roof on the coach, I finished chopping off the existing top. Along with the A and B-pillars:

The bubble wrap and tape were there to protect the parts I was not cutting.

Having joined the two car bodies together, I now had to cut a new line for the rear door and eliminate the seam.

I taped off the door handle and other parts I did not want to get body filler on and then sanded it all down smooth.

Spraying on some grey primer I was able to see what little imperfections there were and sand a little more.

The next thing to do is sculpt the basic shape of the upper part of the car in balsa wood and styrene. This will just be to create the outer portion of the mold around. After that, it can be discarded and the interior can be constructed.

Saturday, October 3, 2015

Two become ONE!

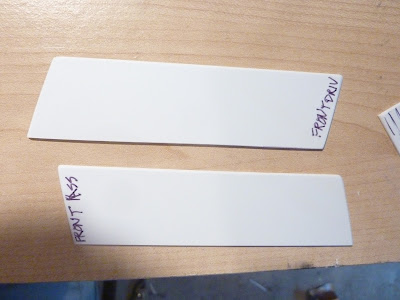

Then did the opposite for the "front donor" car.

Used a grinder to level the rear door handles...

And then used body filler to "erase" the rear doors all together.

After a little sanding...

I glued both halves into place on a steady board and put tape over the seams to keep the J-B Weld from oozing through to the visible side of the car.

After the epoxy sets, I'll use more bondo on the outside and cut a line for the the rear door.

Rear bumper modifications

I cut the frame from the lid with the rotary cutter,

On the left you can see what I was trying to achieve. I decided to temporarily hot glue the license frame in place and then use some two-part J-B Weld epoxy on the backside of it to bond the pieces together.

Subscribe to:

Comments (Atom)